JL Audio XD 600/1 is a mono class D amplifier designed to power a car subwoofer. The amplifier has a power of 600W RMS at a load of 2 ohms. The presented specimen plays in the SQ (Sound Quality) system, and all introduced modifications were made with the aim of obtaining the highest possible sound quality. The work on this amplifier has greatly expanded my knowledge in the field of processing the lowest frequencies and confirmed how much the subwoofer influences the reception of the entire acoustic band, despite working in a very narrow frequency range (the low-pass filter of the amplifier is set to 65Hz/24dB/oct). The physical conditions in the car cause that the subwoofer, by its location (usually in the trunk) will always introduce some distortions, but I did not expected that so much of this interferences was emitted by the amplifier itself, which is not the cheapest construction. I consider the JL Audio XD 600/1 to be a good amplifier, worth it’s price, but the changes I’ve introduced have shown that much more can be obtained from this construction. Changes also showed that despite the placement of the subwoofer in the trunk, even small changes in the amplifier can significantly improve the reception of the entire audio system.

The factory XD600/1 presents the sound typical of the JL Audio constructions, the bass is compact, fast and precise. However, he lacks diversity, musicality and naturalness. I have always suspected that for those disadvantages were responsible loudspeakers that cooperated with the amplifier (Rainbown Vanadium 10 ‘, Hertz HX 300D), but it turned out that the problem was in the amplifier, which after the introduced changes significantly changed its face and now presents a completely different class of sound.

Subwoofer is irreplaceable element in car audio system, controversial in home audio system. There are people who can not live without it and those who can not stand the presence of a single bass speaker in the home audio system. I belong to the group of people who think that a single bass speaker in the home audio system introduces too much chaos on the stage and I hear it even when the subwoofer works with frequencies not exceeding 100Hz. People who decide to use a subwoofer should know that it is an integral part of the system, and it can not be simply turned on and off because turning off the subwoofer affects the other ranges of the audio band. Changes can be heard even in the reception of the highest registers, which become sharper and more present. Understanding the relationship and interconnection of all ranges of the acoustic band gives an idea of how much can be changed in the whole system, through changes even for a small acoustic range.

Construction of the amplifier

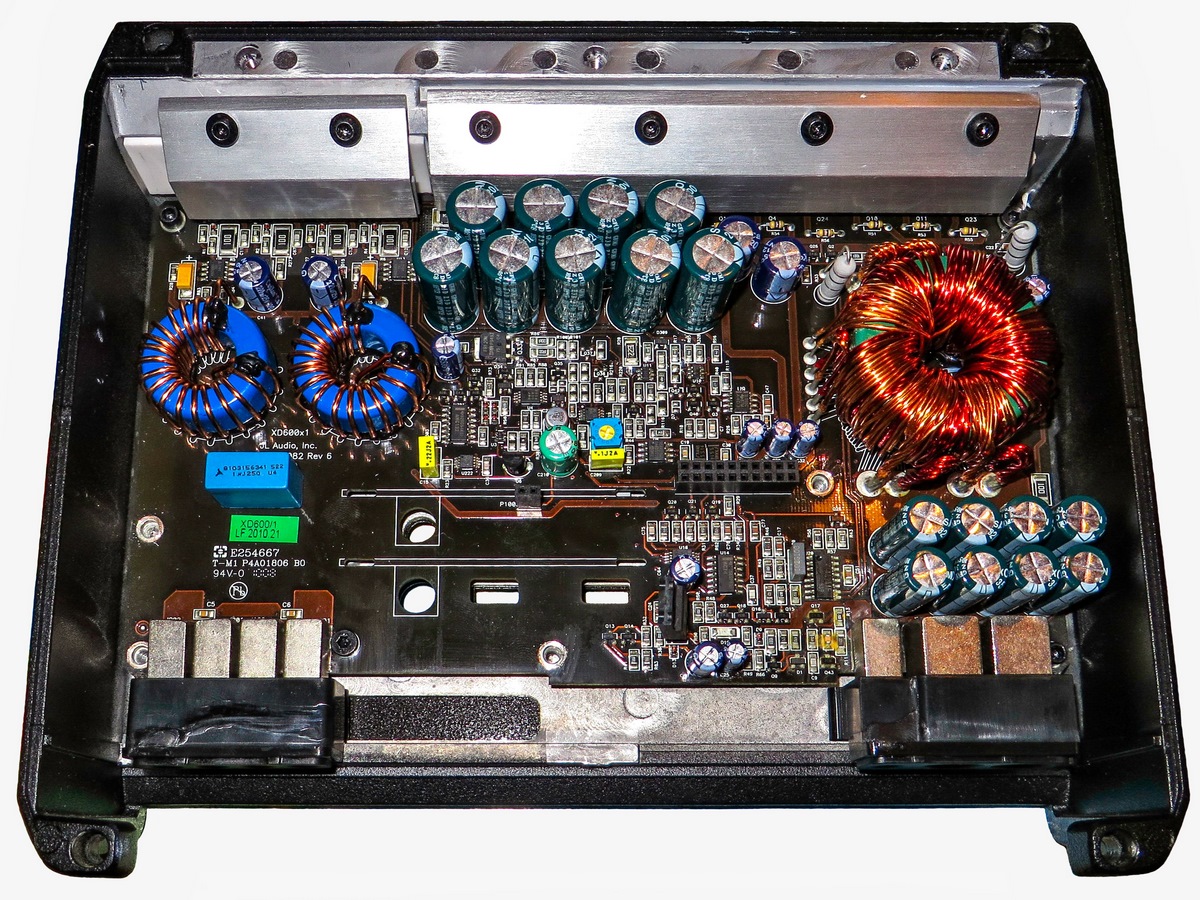

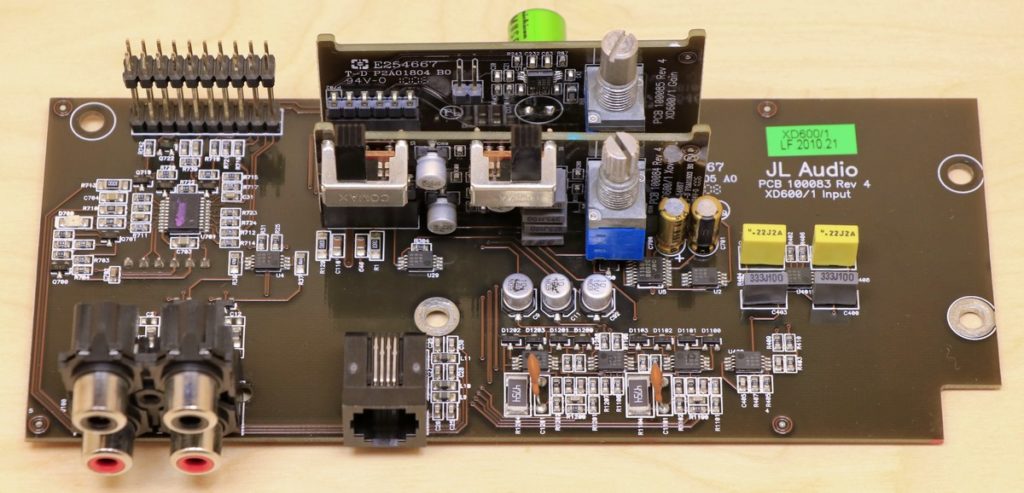

At the beginning I will briefly describe the construction of the amplifier so that the terminology I use is better understood. I do not intend to write about each block and its structure, I only describe what each of the amplifier’s PCBs is responsible for. The amplifier consists of 4 separate PCBs. The whole structure can be divided into two basic modules.

Amplifier module, containing power elements (converter, stabilizers) and the class D amplifier itself.

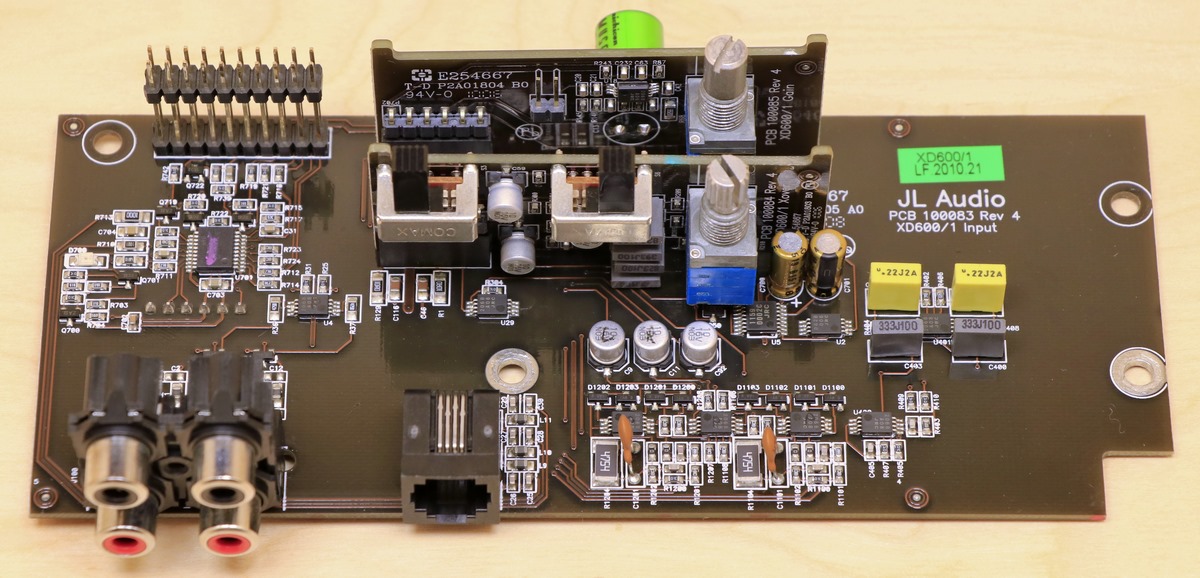

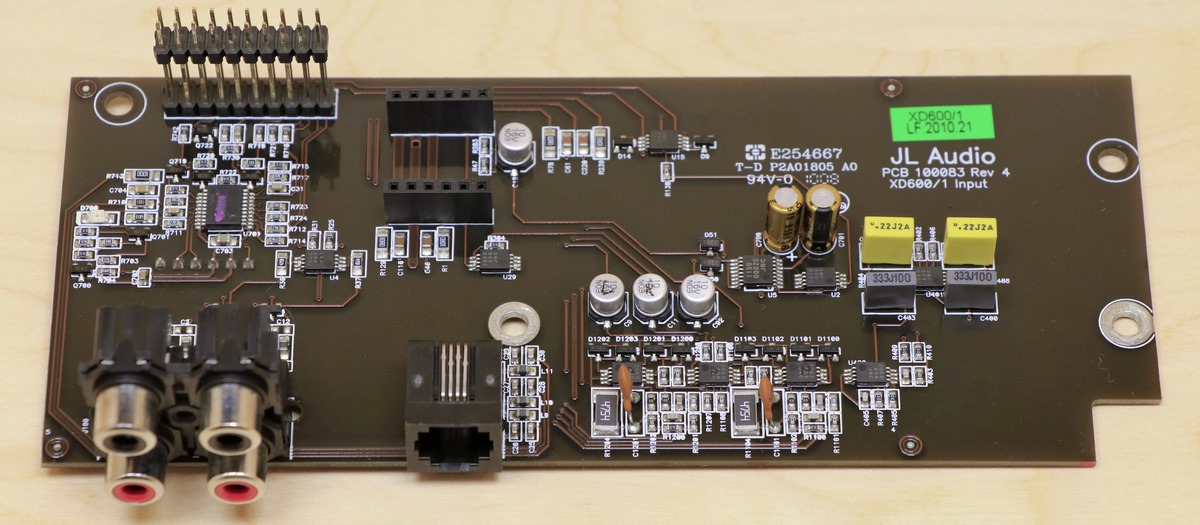

Signal module, which is responsible for processing the audio signal, which then goes to the amplifier module. The signal module is responsible for receiving the signal from the sound source, adding up the signal (conversion stereo signal into mono), passing the signal through the low-pass filter (LPF) and adjusting the signal level (GAIN).

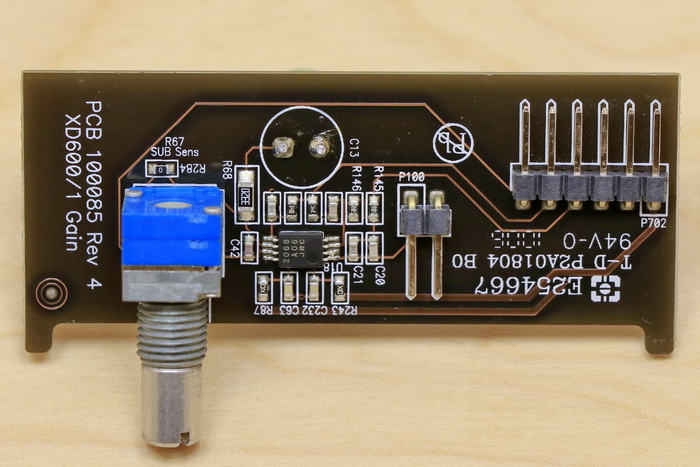

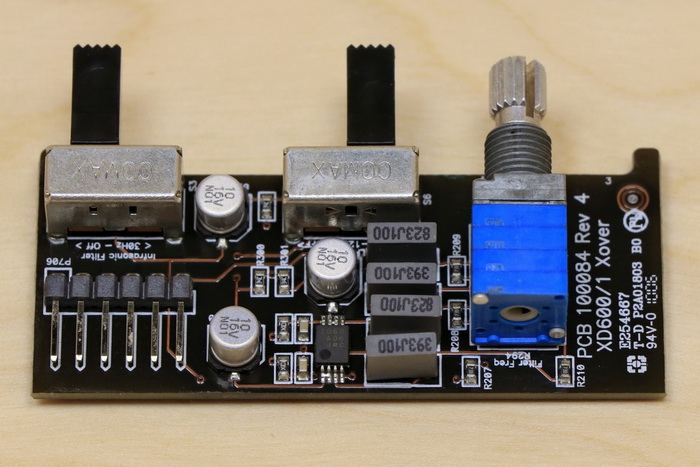

GAIN adjustment and LPF filter were placed on separate PCBs. In addition, the signal module contains elements responsible for the PreOut output operation and the control of an additional external potentiometer for volume control.

This solution allows to preserve the compact design of the device, but combining the PCBs by copper pins can have a negative effect on the power supply quality of the active components and the transmission of the audio signal. Fortunately, the producer was aware of this disadvantage and the vast majority of paths are connected via at least 2 pins. The compact design also means that interference from the converter (which is not shielded) can be applied to an audio signal.

Replacing power capacitors

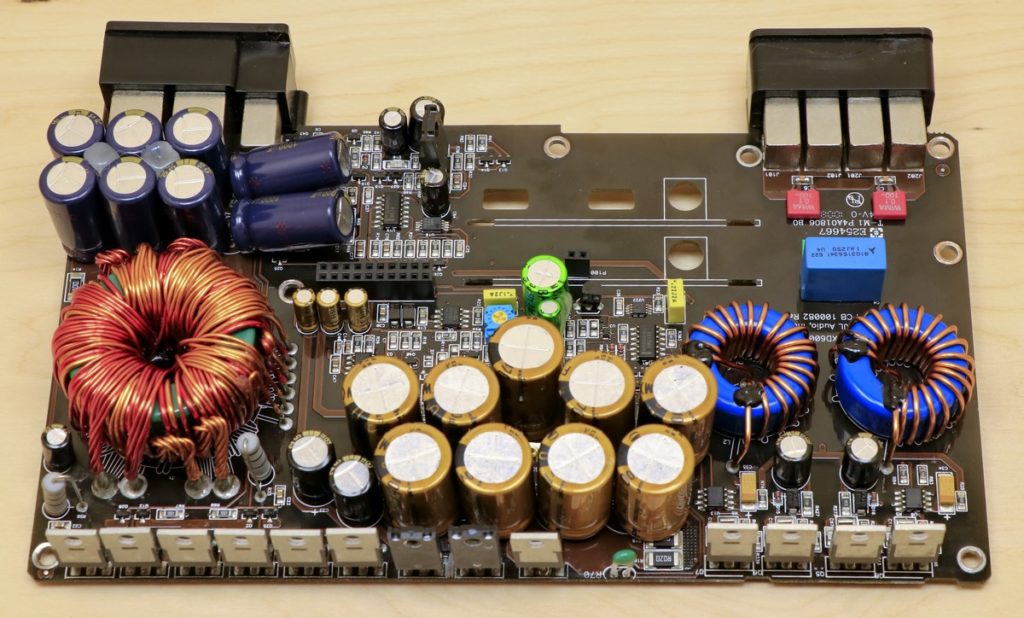

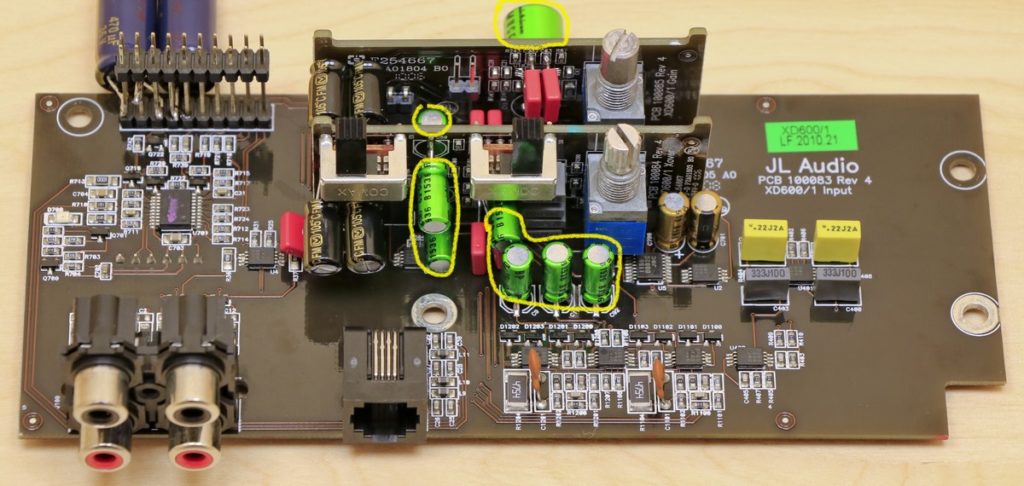

The amplifier has two batteries of power capacitors. The first capacitors battery is at the amplifier’s power supply input and consists of 8 capacitors with a capacity of 820uF. The second capacitors battery is located behind the converter and is a current reserve for the power amplifier, consisting of 9 capacitors with a capacity of 220uF.

The use of a large number of capacitors is a good solution for this construction. The battery of parallel connected capacitors has a much lower series resistance, which at high power, has a significant impact on the efficiency and effective operation of such a buffer.

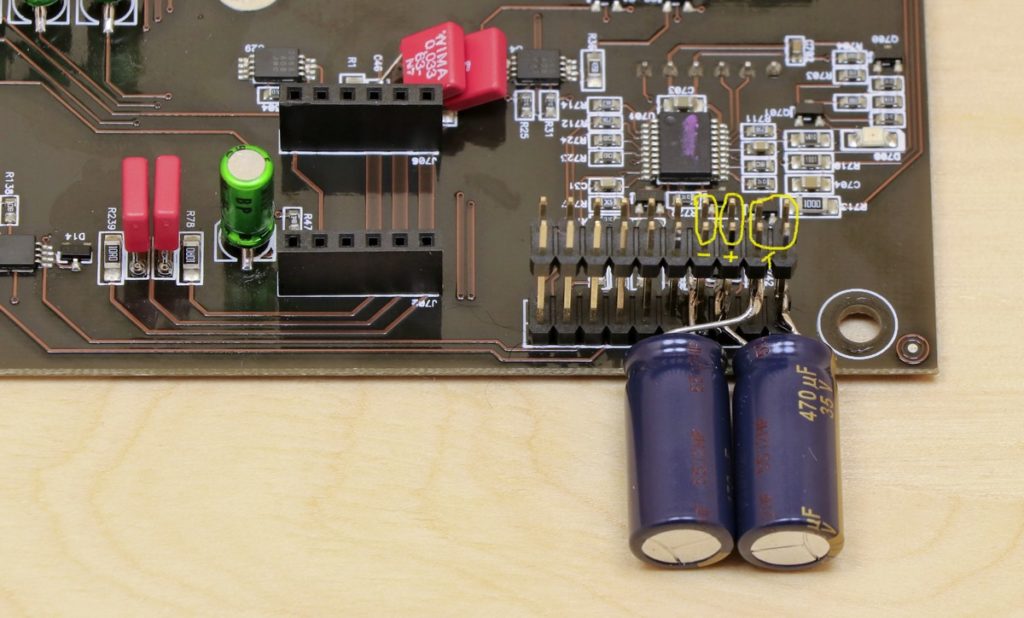

When selecting the capacitors that were to replace the factory capacitors from SAMXON, the basic criterion was to keep the same number of capacitors and then to obtain the largest possible capacity. On the amplifier’s power input hit the PANASONIC FC capacitors with a capacity of 1000uF and voltage of 35V. The second battery behind the converter has been replaced by NICHICON FW capacitors. I have not used the NICHICON FW capacitors before and I decided to use them mainly because of their size, which allowed to use capacitors with a capacity of 470uF, instead of factory 220uF. At the beginning I was a bit skeptical about the Nichicon FW capacitors, so I decided to use the RLC laboratory meter to measure them. Thanks to this, I was able to check if the capacitors I chose have better parameters than factory capacitors.

The table below shows the results of measurements of series resistance of SAMXON factory capacitors, NICHICON FW and PANASONIC FC.

|

Series resistance |

Series battery resistance |

Battery capacity |

|

|

SAMXON 220uF 100V |

0,076 ohm |

0,0084 ohm |

1980uF |

|

Nichicon FW 470uF 100V |

0,052 ohm |

0,0057 ohm |

4230uF |

|

SAMXON 820uF 35V |

0,036 ohm |

0,0045 ohm |

6560uF |

|

Panasonic FM 1000uF 35V |

0,022 ohm |

0,0028 ohm |

8000uF |

As can be seen in the table above, the replacement of capacitors has been beneficial in terms of both series resistance and capacitance. Particularly the replacement of capacitors to Nichicon FW resulted in more than double the capacity increase.

The measurements were made for frequencies from 1kHz to 10kHz, therefore they may differ from the catalog data. However, the main purpose of the measurements was to check the differences between the capacitors, and not verify the catalog data.

Differences in the values in the table are not only measurable, but also audible, especially at powers exceeding value 200W. The amplifier with factory capacitors was doing well, even with a nominal power of 600W. However, the exchange of capacitors showed that especially in the area of higher powers there were big changes in the dynamics. The amplifier is doing much better now and playing with more freedom.

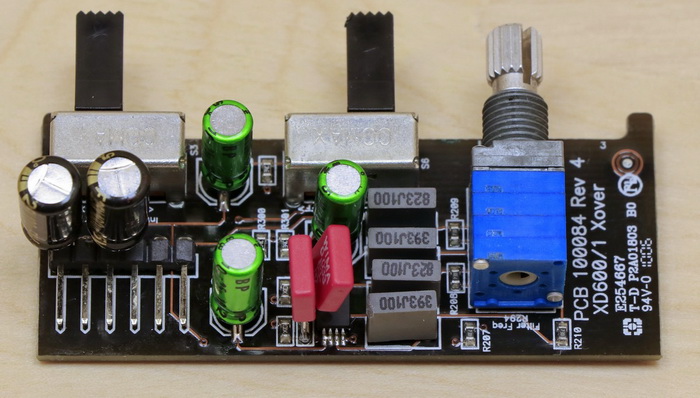

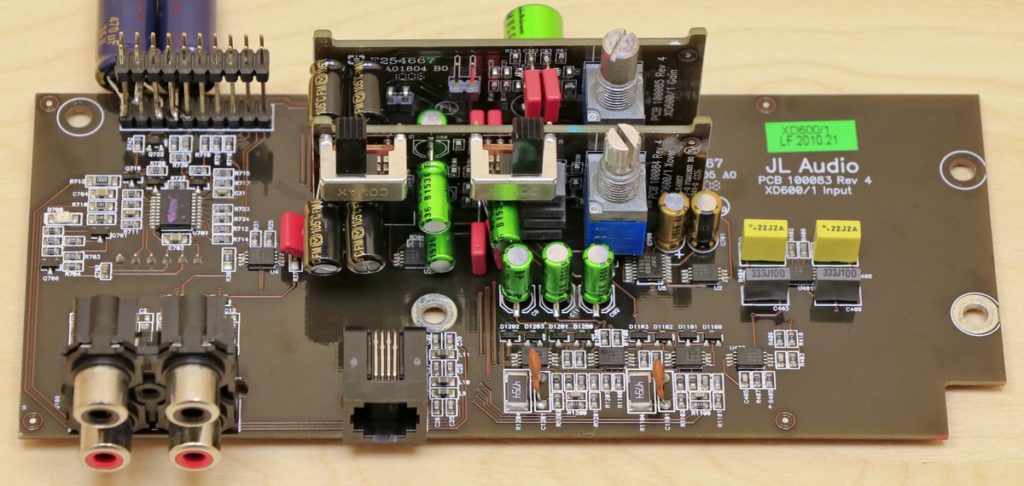

The dimensions of the Nichicon FW and Panasonic FC capacitors are larger than the dimensions of factory capacitors, but the method of their assembly does not conflict and does not affect the other elements. The other electrolytic capacitors on the amplifier board are Panasonic FM, which I used because of their warm sound character. Also on the PCB are Nichicon FG capacitors which work well with Panasonic FM capacitors.

Addition of decoupling capacitors

Adding decoupling capacitors is one of the basic treatments during my modifications. In today’s audio devices a lot of attention is attached to this issue, but the common solution in the form of SMD surface elements makes that you can still gain a lot in this field. SMD capacitors have significantly worse interference filtering capacities than leaded foil capacitors, but their great advantage is the price and the ability to automate production, and thus reduce costs. Another advantage of SMD capacitors is their small size. This allows to bring the mass as close as possible to the power path, and such physical conditions in turn improve the efficiency of filtration. All this makes that sometimes it is not worth replacing the SMD capacitor with a foil capacitor. The best effects are obtained by combining both solutions, SMD and foil capacitor.

Amplifier module

There are many power decoupling points in the XD600/1 amplifier, which deserves praise. In some of the decoupling points there are no capacitors and empty places were left. Maybe it was considered that in the production version the assembly of capacitors at these points does not affect the improvement of quality. Sometimes too many decoupling capacitors can calm down the sound too much, so more does not always mean better. Of course, I decided to use available places and see how amplifier will reacts to this change.

As a decoupling capacitors I used WIMA MKS2 capacitors. In the case of this modification, I used 33nF capacitors. I usually use capacitors with a capacity of 100nF, but I decided that the capacity of 33uF will be safer in this case and will not negative affect the dynamics of the signal.

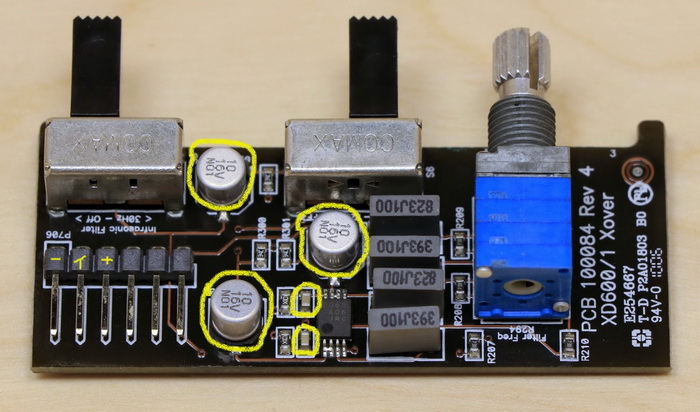

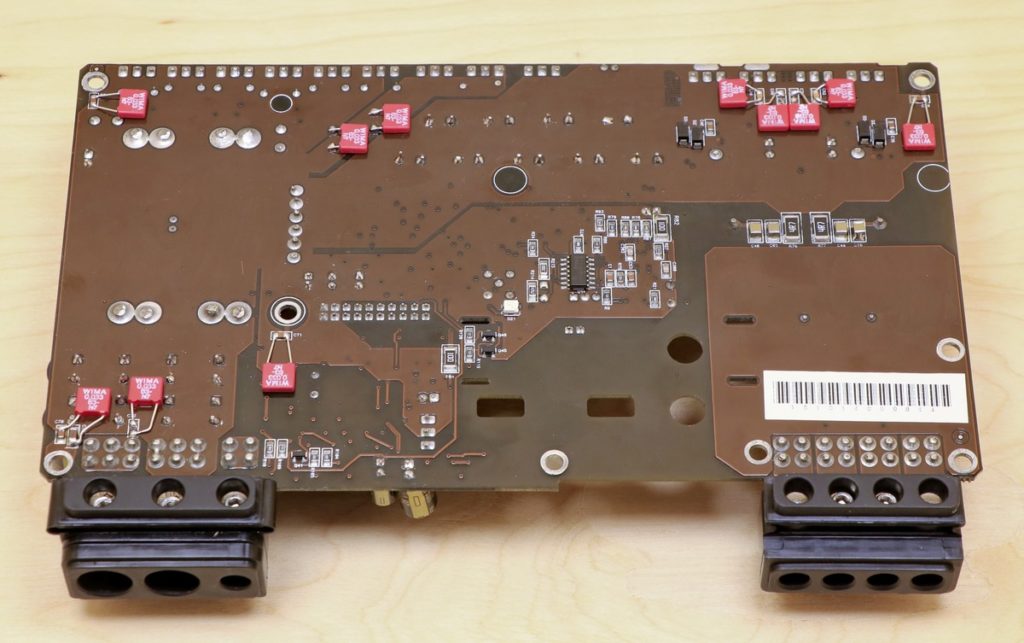

In the picture below can be seen the bottom part of the amplifier PCB, with added WIMA MKS2 decoupling capacitors. The most important places for this PCB is located in the lower left corner, where the decoupling capacitor was omitted at the very entrance of power supply of the amplifier, and in the upper right corner, where there are capacitors decoupling the power transistors. For the power output stage transistors is provided space for 4 SMD capacitors. The selection of decoupling capacitors for power transistors can be understood, but I don’t understand the lack of a decoupling capacitor at the power supply entrance and I consider it to be an excessive saving.

Signal module

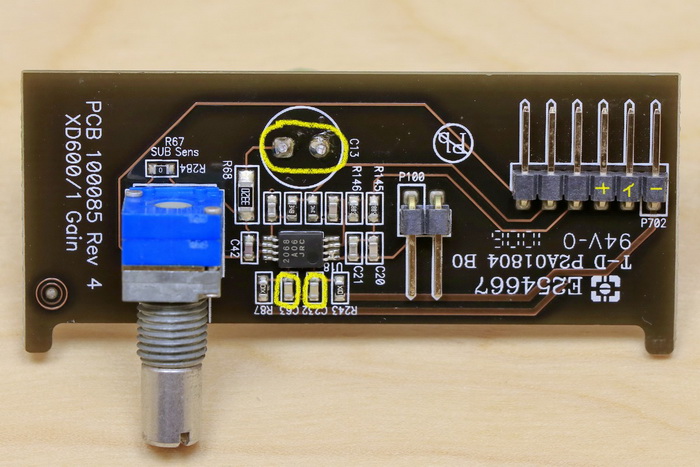

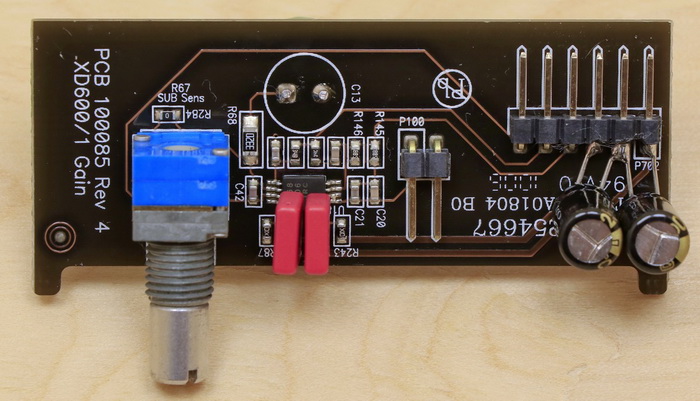

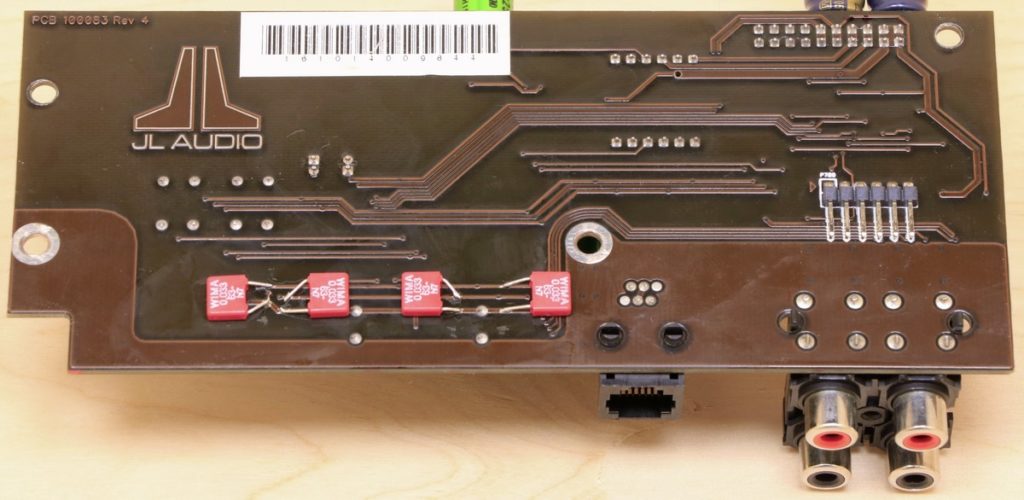

The module contains 10 NJM2068 operational amplifiers. Part of the opamps are not provided with decoupling capacitors. These are opamps located next to external volume control socket, responsible for the PreOut output operation and for adding up the input signal (creating a mono signal for the power amplifier). I was able to add decoupling capacitors for these operational amplifiers by adding four capacitors to the power paths from the bottom of the PCB. In places where decoupling capacitors have been provided, WIMA MKS2 have been added to the SMD capacitors. In the pictures below, there are also Panasonic FM capacitors added for GAIN control and LPF filter power supply paths as well as Nichicon MUSE ES capacitors. Detailed information about them can be found in the next points of the modification.

Summary of addition of decoupling capacitors

I was very curious about what change I will get after adding decoupling capacitors in this amplifier. For amplifiers working in the full acoustic range, the effect is usually positive, but the biggest changes occur in the medium and upper band range, while in the lowest frequency range, they could even be unnoticeable. My fears dissipated after a moment of listening. I was amazed at how much the range of lower frequencies was cleansed. I have always suspected that the physical conditions prevailing in my car are main reason of the problems with the quality of the lower frequency range, but it turned out that the problem was also in the amplifier. The lower frequencies has gained more space and the so-called “black background”. XD600/1 is a construction that generates a lot of interference, the main source of which is the converter and EMI distortions characteristic of a class D amplifiers. All these distortions are frequencies of tens of kHz, but they must have a significant impact on the amplifier’s audio signal processing, even for such a narrow range of work, since the changes are clearly audible.

Addition of electrolytic capacitors in the audio signal processing module

In SQ (sound quality) systems, tens of watts of power can be a problem that requires optimization of the design in terms of current flow in order to obtain the least possible losses and the greatest possible efficiency of the device. The amplifier XD600/1 has a nominal power of 600W RMS at a load of 2 ohms, which gives a current of 17A with nominal power. This is the current generated by the power output stage, and the converter, which is responsible for providing this current, also supports all other components, such as voltage stabilizers supplying active components, including operational amplifiers. I began to wonder, how much impact on the power supply stability of the operational amplifiers has the load of the converter. From my experience I know that voltage stabilizing circuits, poorly cope with its stabilization of power supply for audio components (they are simply too slow) but in this case converter still has to power up amplifier output stage, which translates into the quality of voltage supplied on the input of the stabilizing circuits. I suspected that when working with high powers, there could be negative feedback, which can deform the audio signal, processing by operational amplifiers due to fluctuations in the power supplied by the converter. Deformation increases as the converter load increases, that is increase in power of the amplifier and worsens the quality of the output signal.

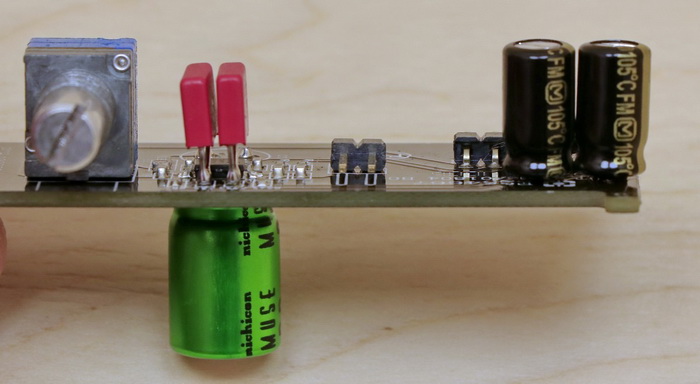

I decided to put electrolytic capacitors on the power supply connection pins. I added Panasonic FC capacitors 470uF to the main signal board. PCB of low-pass filter and GAIN control also received additional Panasonic FM electrolytic capacitors of a capacity 100uF (shown in the pictures above, at the point with the decoupling capacitors).

The changes introduced by this modification have been very positive. The amplifier gained a bit warmer sound thanks to the characteristics of Panasonic FC/FM capacitors. My suspicions of distortion for larger powers have also been confirmed. Now the amplifier is doing much better. The dynamics and precision increased, more air and order appeared in the lower frequency range. In conclusion, the addition of electrolytic capacitors in power supply of opamps was a very good idea and positively influenced the stability of operational amplifiers, which in a straight line translates into better quality of the audio signal at the power amplifier input and a clear increase in dynamics for higher powers.

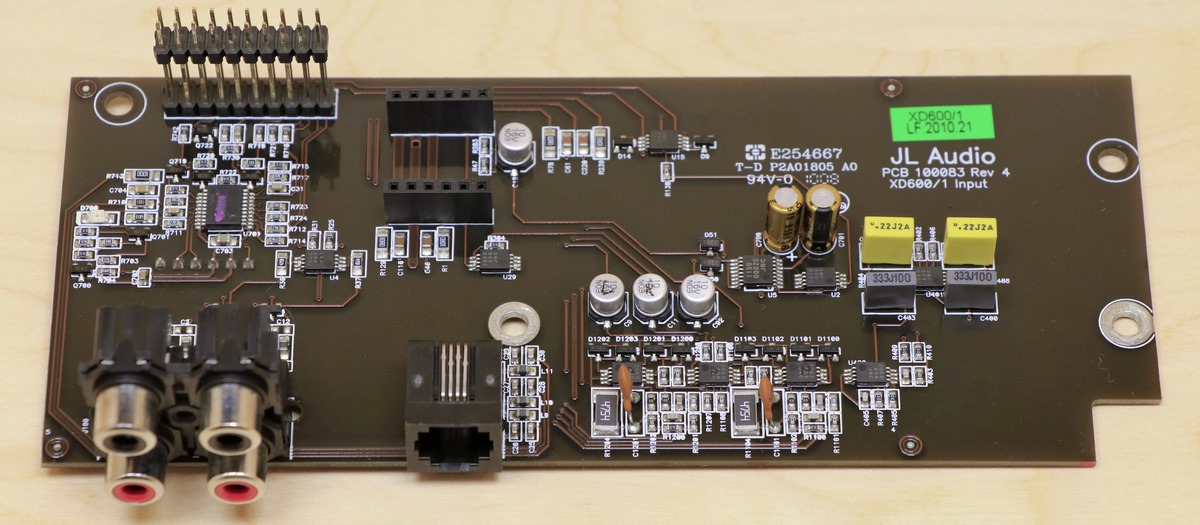

Capacitor exchange in the signal path

There are many electrolytic coupling capacitors in the signal path of the amplifier. The producer made sure that the subsequent sections of the amplifier were separated from each other. Personally, I am a supporter of the least amount of electrolytic capacitors in the signal path, but in this case I understand the intentions of the producer and decided that I will not reduce their number.

Unfortunately, I can’t tell what SMD capacitors (company / model) was used in the amplifier, I only know their capacity, which is 10uF. I have decided that all capacitors will be replaced into Nichicon MUSE ES. I knew that Nichicon ES will bring positive changes, I did not know just how big the changes will be and what their character will be for the amplifier working in the lowest frequencies range. Most of the capacitors installed are SMD constructions, only 2 capacitors with capacity of 100uF are lead-through components. Due to the larger size of the Nichicon ES 100uF capacitor, I had to solder the capacitor from the other side of the PCB on the GAIN module. Nichicon MUSE ES capacitors have once again shown their class. Bass gained in openness, it became deeper and more pleasant for ear.

Summary

I am very happy with the results I have achieved and I am not exaggerating writing that the amplifier has gained a second life. Depth and bass space have changed significantly. The dynamics have increased, the contours are much more pronounced, and the kick of the bass gives the impression of wanting to break off the head. XD 600/1 has very grown up, the lower registers are still fast and compact, but they have gained transparency and cleanliness. Another positive effect of the modification is the wider range of subwoofer level regulation. In my system, I always had a problem when I wanted to increase the subwoofer level for weaker recordings. Increasing the volume of the subwoofer has always been associated with reduced dynamics, the effect of merging and limiting the space of the lower ranges. After modification, this phenomenon has disappeared, regardless of the level of the subwoofer, the bass is fast and spatial. I do not expected changes in this aspect, because I always suspected that car acoustic properties are responsible for those distortions when increasing the subwoofer’s volume level.

The entirety of sound presented by my system at higher volumes has also changed significantly. Even when operating at 600W nominal power, the subwoofer still maintains high sound quality and give a lot of pleasure. After modifying the amplifier, the bass gained a completely different dimension and is so mesmerizing that sometimes it is difficult to master yourself and not use the full power amplifier. Only after the completion of the modification I realized how many chaos was introduced by subwoofer in my system and how much the amplifier had to do with it. Now it is much better and the “mixing” of the system has improved. When I started working with this amplifier I did not expect such big changes.